Chemical engineering researchers at the University of Waterloo have joined forces to take on a pressing environmental problem by using synthetic biology to turn plastic waste into valuable resources. The multidisciplinary group is working together to review and identify strategies that leverage synthetic biology, microbial engineering and engineering design to degrade and upcycle plastic waste.

“We’re stepping out of our silos to advance sustainability,” says Dr. Marc Aucoin, a professor in the Department of Chemical Engineering. “If we work together, we have a broader base to attack this issue.” Their recent review of the problem is published in the Canadian Journal of Microbiology.

The scale of the challenge

The plastic waste crisis is one of the great challenges facing humanity. According to the United Nations Environment Program, 19 to 23 million tons of plastic waste leak into ecosystems annually. These plastics take hundreds of years to break down and are now degrading into nano and micro plastics.

A promising solution lies in creating a circular economy in which plastics at the end of their lives are consistently used to generate new, valuable products, rather than ending up as harmful waste in oceans and landfills. That’s where members of the Waterloo research group, which includes Aucoin and colleagues Drs. Christian Euler, Brian Ingalls, Yilan Liu and Elisabeth Prince, come in.

Biotechnological solutions to plastic waste may be cost-effective in upcycling plastics into valuable products, and since traditional recycling methods rely on harsh chemicals and high temperatures, using synthetic biology to engineer organisms and biological systems offers a gentler way forward.

A greener path to recycling

Euler, a chemical engineering professor and Waterloo’s lead for the Center for Innovative Recycling and Circular Economy (CIRCLE), is developing novel microbial pathways to valorize plastic waste.

In a recent study in the journal PLOS Computational Biology, Euler’s research group investigated whether feedstocks derived from plastic waste could provide the energy to drive carbon dioxide (CO₂) conversion.

The group analyzed how certain organisms metabolize both CO₂ and plastic waste simultaneously—a strategy called mixotrophy in which “mix” means combining multiple foods and “troph” means eating. This approach may allow micro-organisms to process multiple carbon sources at once, which is unusual since most microbes typically consume only one type of “food” at a time.

The research demonstrated that several waste-derived carbon sources—especially those from plastic—could support the microbial conversion of CO₂ into valuable products, addressing two environmental problems at once.

The results served to highlight that developing new methods to break down plastics at their source, such as in wastewater treatment plants, is critical. Degrading plastics before they reach natural ecosystems could significantly reduce environmental contamination.

To address this challenge, Aucoin, Ingalls (a mathematics professor who is cross-appointed to biology and chemical engineering), and Aaron Yip, a former Ph.D. student, developed a process that degrades polyethylene terephthalate (PET) plastics via an enzyme found in nature.

Their goal is to spread the enzyme, or the genetic information for the enzyme, throughout a population of organisms found in municipal wastewater.

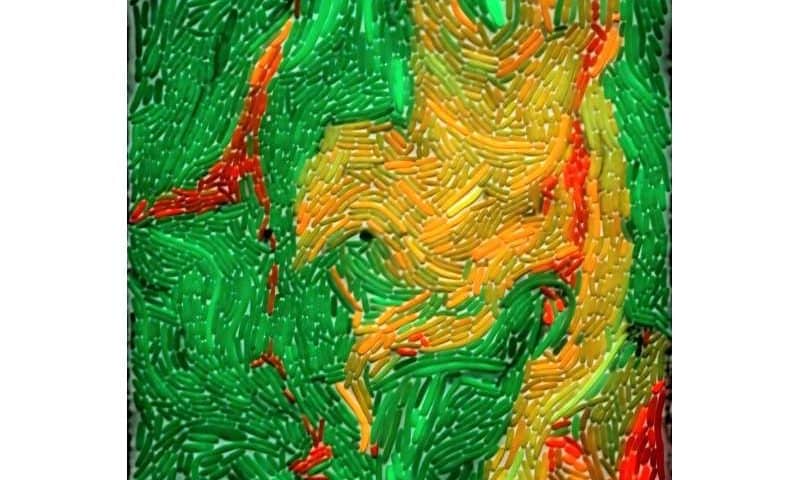

Liu, also a professor of chemical engineering, is taking a different approach by evolving microbes to “eat” plastics as their only food source. Her research group is engineering synthetic symbiotic bacterial consortia for the bioconversion of plastic waste.

Building a circular plastics economy

Prince is approaching the problem from a different angle by looking at how plastics are designed in the first place.

She developed a method to make thermoset polymers and rubbers recyclable using existing manufacturing infrastructure, requiring only minor formulation changes. This strategy could make currently non-recyclable materials like rubber tires, epoxy coatings and elastic bands part of a sustainable, circular system.

“When we talk about grand challenges in the world, each of us could say our work is a small piece of the solution,” Euler says. “But when we bring our different expertise together, we’re creating a community that is truly collaborative. We’re not just working in our own spheres—we’re building something new together.”